"What are the important tests in the manufacture of DONGS machine tool equipment?

Jul 22,2025

Author:

In the manufacturing industry, the performance and accuracy of machine tools directly affect the quality and productivity of products. Therefore, DONGS machine tools are manufactured with specialised measuring tools and equipment to accurately measure each component of the machine to ensure that it meets the design standards.

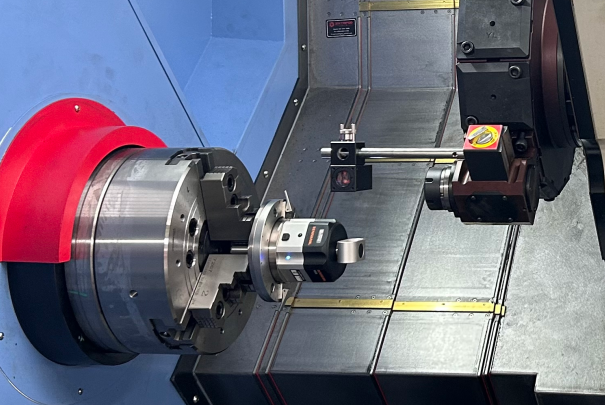

Spindle inspection mounting

Spindle as a core component in mechanical equipment, its performance directly affects the efficiency and machining accuracy of the entire equipment. Therefore, when carrying out spindle installation, a series of standards and processes need to be followed to ensure the normal operation of the spindle and the stability of the equipment.

Spindle inspection and installation requires technicians with professional knowledge and rich experience to ensure the correct installation and normal operation of the spindle. Through strict testing and scientific installation process, it can greatly improve the service life and processing quality of mechanical equipment.

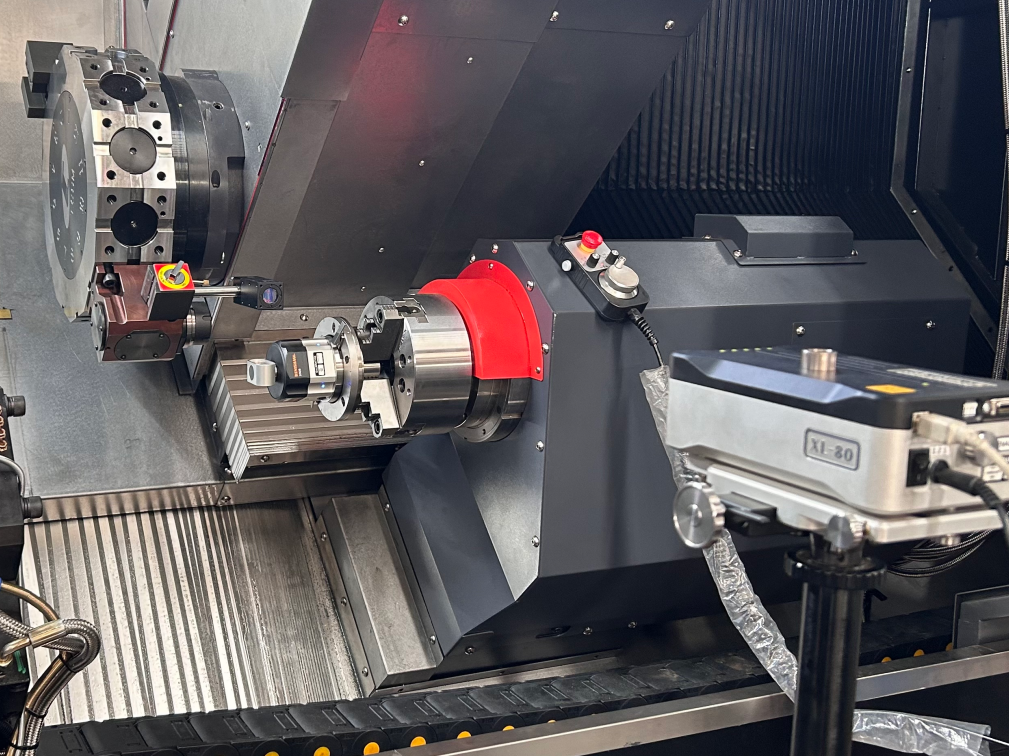

Guideway Straightness Inspection

Guide rail straightness testing is mainly to ensure that the guide rail can be installed in the working state to maintain good straightness, so as to facilitate the smooth operation of mechanical components, the straightness of the guide rail directly affects the performance and accuracy of the equipment. The use of a series of professional testing tools and equipment instruments to help technicians accurately measure the straightness of the guide rail, timely detection and correction of existing problems. Ensure that the data of each measurement point can reflect the true state of the guideway.

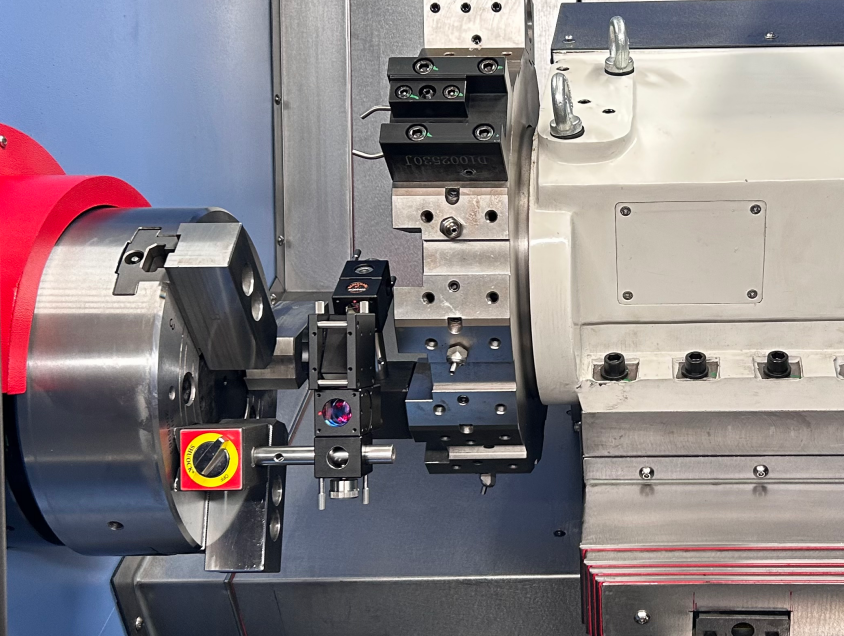

C-axis laser inspection

‘Laser inspection’ is a cutting-edge technology that plays a vital role in a variety of industrial applications.

By focusing on the C-axis (which refers to the axis of rotation in the coordinate system), the laser captures data points at different angles as the object is rotated around the C-axis, allowing the entire surface to be fully analysed. This real-time data acquisition improves measurement accuracy and ensures product performance drink quality.

B-axis laser inspection

The B-axis is a rotational axis that can be moved around a vertical line, allowing the laser to scan an object from different angles. With the ability to detect the smallest defects using a B-axis laser inspection system, DONGS manufacturers can ensure that their products meet strict specifications and standards.

X-axis laser inspection

‘X-axis laser inspection’ is the precise measurement and analysis of the X-axis position of a specific object or system using a laser beam. This method is particularly suitable for a wide range of industrial applications where extreme precision is required, such as manufacturing processes, quality control and automation systems.

Due to time factors DONGS machine tool to share this part of the inspection content, later to share please pay attention to DONGS machine tool.

lathe cnc machine,CNC Machine Tool,torno cnc,cnc machine,cnc turning machine,metal lathe machine,CNC Lathe Machine for Metal

Contact Us

Tel: +86-13371109792

E-mail:dssklcc@outlook.com

Company Address: No. 669, Shannan East Road, Tengzhou City, Shandong Provin